Distribution board

This article needs attention from an expert in article. Please add a reason or a talk parameter to this template to explain the issue with the article. (November 2008) |

A distribution board divides the electrical mains feed into various circuits, providing a fuse or circuit breaker for each circuit. They usually include a main switch, and often one or more Residual-current devices (RCD) or Residual Current Breakers with Overcurrent protection (RCBO).

Other names

Distribution boards are sometimes known as

- breaker panel

- fusebox

- fuseboard

- circuit breaker panel

- consumer unit, or CU

- panelboard

- load centre (center in North America)

North American breaker panels

The circuit breakers are generally placed in two columns. Circuit breaker panels are always dead front, that is, the operator of the circuit breakers cannot contact live electrical parts. During servicing of the distribution board itself, though, when the cover has been removed and the cables are visible, North American breaker panels commonly have some live parts exposed.

Breaker arrangement

Breakers are usually arranged in two columns. In a US-style board, breaker positions are numbered left-to-right, along each row from top to bottom. This numbering system is universal across various competing manufacturers of breaker panels.

| Split Phase | 3-Phase | Breakers | |

|---|---|---|---|

| A | A | 1 | 2 |

| B | B | 3 | 4 |

| A | C | 5 | 6 |

| B | A | 7 | 8 |

| A | B | 9 | 10 |

| B | C | 11 | 12 |

Each row is fed from a different phase (A, B and C below), to allow 2- or 3-pole common-trip breakers to have one pole on each phase.

For 120/240 volts, hot (live) wires are black and red; neutral is white. In 208Y/120 volt three-phase power, the third phase is blue. For 480Y/277 volts (always three-phase) the hot wires are brown, orange and yellow, and grey is the neutral. Green or bare wires are used as grounds in both configurations. The 208Y/120 volt and 480Y/277 volt systems are both wye systems. All three phases in these systems measure either 120 or 277 volts to the neutral and 208 or 480 volts to each other. Another common system seen in older buildings is the 240D/120 center tap delta system. In this system, two phases (phase A and phase C) measure 120 volts to the neutral. Phase B in this system is a high leg aka a "stinger" leg that measures 208 volts to the neutral. Every second and fifth slot in a panel fed with this system connects with the stinger leg and must not be used to supply 120 volt single phase loads. However the stinger can be used as part of a 240 volt single or three phase circuit. Most buildings with 240D/120 service don't feed all three phases into the lighting/small appliance panel. The two 120 volt to neutral phases are split out of the main supply entrance and feed a 120/240 single phase lighting/small appliance panel. The third phase in this system is only used for air conditioning and other large motor loads. Almost all new buildings with three-phase service use the 208Y/120 volt system thus eliminating the stinger leg problem.

In North America it is common to wire large heating equipment line-to-line. This takes two slots in the panel (two-pole) and gives a voltage of 240V if the supply system is split phase and 208 V if the supply system is three phase. This practice is much less common in countries that use a higher line-neutral voltage. Large motors, air conditioners, subpanels, etc., are typically three-phase (where available). A three-pole breaker is required, which takes three slots in the breaker panel and three slots are punched out of the front cover to accept the additional circuit breaker.

Inside a North American panel

The picture to the right shows the interior of a standard residential service, North American General Electric style breaker panel. The three power lines can be seen coming in at the top (One going to the neutral busbar to the left with all the white wires, the other two attached to the main breaker). Below it are the two rows of circuit breakers with the circuit's hot wire leading off. A line can be seen directly exiting the box and running to a NEMA 5-15 electrical receptacle with a power cord plugged into it.

UK Fuseboxes (Consumer Units)

In the UK, domestic CUs usually fall into two categories:

- Modern CU with MCBs and an RCD,

- Older CU, usually containing no RCD.

Domestic fuseboxes/CUs normally have the breakers or fuses arranged in a single horizontal row. Twin vertical row boxes are seen in commercial premises where a greater number of ways is required.

Modern CU

A typical new domestic CU used as a main panel may have anything from 6 to 12 ways for MCBs. Secondary CUs used for outbuildings usually have 1 or 2 ways. Most CUs have one RCD built in, but not all. These boxes are frequently white or grey. Split CUs are now popular in new installs. Commercial CUs are larger with more ways.

In the main the term fuse box is misused, due to the fact the most design consists of no fuses, and merely work by sensing the difference in voltage across the appliance and will "trip" a switch if a surge occurs.

New British distribution boards generally have the live parts enclosed to IP20, even when the cover has been removed for servicing.

Older fusebox

Older fuseboxes usually use rewirable fuses with no other protective device, and basic 4 ways boxes are very common. A lot of these boxes are made of brown-black bakelite, sometimes with a wooden base. Although their design is historic, these were standard equipment for new installs as recently as the 1980s, so are very common.

Users should be wary of these fuseboxes, as typically pulling a fuse carrier out with the power on results in fingers grasping live connections, and these boxes are widespread even in modern installations.

The popular 4 way fusebox usually has 2 lighting and 2 socket circuits, with heavy or sustained loads such as immersion heater and oven on a socket circuit. This arrangement is not recommended practice today, but it is common in existing installations. Larger boxes with more ways will have separate fuses for large loads such as immersion heater, oven and shower.

MCB Retrofits

Some of these fuseboxes have had their fuse carriers relaced with plug-in MCBs. These retrofit MCBs are typically rated at 3kA breaking capacity, but many homes or properties have PSCCs as high as 6kA. Hence these MCBs do not have sufficient breaking capacity for safe reliable operation in many premises.

Historic Fuseboxes

A small number of pre-1950 fuseboxes are still in service. These should be treated with caution because exposed live parts are common on these boxes. The installations they supply are will not meet modern standards for electrical safety. Another characteristic of older UK fuseboxes is that there may be two fuses for each circuit - one on the live and one on the neutral. In rare instances, old ring circuits may be encountered with no less than 4 15A fuses per ring, one on each of L and N, and this duplicated for each of the 2 feeds for the ring.

Split CUs

A split CU is one CU divided electrically into two halves, each of which is switched independently. These are popular in new installs in the UK. They allow power to remain on in some circuits, while work can be carried in the other. As well, one main switch is replaced by an RCD allowing both RCD and non-RCD circuits.

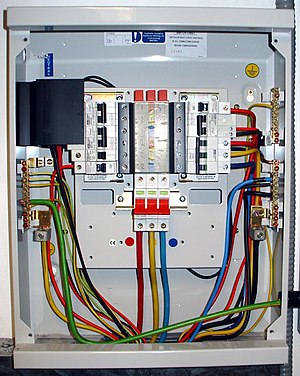

Inside a UK distribution board

This picture shows the interior of a typical 12-position UK distribution panel. The three incoming phase wires connect to the busbars via an isolator switch in the centre of the panel. On each side of the panel are two busbars, for neutral and earth. The incoming neutral connects to the lower busbar on the right side of the panel, which is in turn connected to the neutral busbar at the top left. The incoming earth wire connects to the lower busbar on the left side of the panel, which is in turn connected to the earth busbar at the top right. The cover has been removed from the lower-right neutral bar; the neutral bar on the left side has its cover in place.

Down the left side of the phase busbars are two two-pole RCBOs and two single-pole breakers, one unused. Down the right side of the busbars are a single-pole breaker, a two-pole RCBO and a three-pole breaker.

The two-pole RCBOs in the picture are not connected across two phases, but have supply-side neutral connections exiting behind the phase busbars.

The illustrated panel includes a great deal of unused space; it is likely that the manufacturer produces 18- and 24-position versions of this panel using the same chassis.

In a UK-style board, breaker positions are numbered top to bottom in the left hand column, then top to bottom in the right column. Each number is used to label one position on each phase, as below, and can be seen faintly in the photograph to the right. It remains to be seen how the new wiring colours recently introduced in the UK will affect this labelling.

| Phase | Breakers | |

|---|---|---|

| Red | R1 | R4 |

| Yellow | Y1 | Y4 |

| Blue | B1 | B4 |

| Red | R2 | R5 |

| Yellow | Y2 | Y5 |

| Blue | B2 | B5 |

| Red | R3 | R6 |

| Yellow | Y3 | Y6 |

| Blue | B3 | B6 |

Manufacturer differences

Most of the time, the panel and the breakers inserted into it must both be from the same company. Each company has one or more "systems", or kinds of breaker panels, that only accept breakers of that type. In Europe this is still the case, despite the adoption of a standard DIN rail for mounting and a standard cut-out shape, as the positions of the busbar connections are not standardised.

It is commonly known in North America that Siemens and General Electric panels and breakers of the type shown in the above and below picture illustrations are seemingly interchangeable one-inch wide breakers. However, an installer must be cautious and abide by all UL or equivalent regulations, as well as any state, federal, or local codes, when modifying systems or installing new overcurrent devices. A given manufacturer will often specify exactly what devices are permitted to be installed in their equipment. This is because these assemblies have been tested and approved for use by a recognized authority. Replacing or adding equipment which "just happens to fit" can result in unexpected or even dangerous conditions. Such installations should not be done without first consulting knowledgeable sources, including manufacturers.

Numerous older systems are still in use in older buildings and parts are still manufactured for these legacy applications, such as Zinsco, Federal-Pacific Electric (F-PE) and others.

Location and designation

For reasons of aesthetics and security, circuit breaker panels are often placed in out-of-the-way closets, attics, garages, or basements, but sometimes they are also featured as part of the aesthetic elements of a building (as an art installation, for example) or where they can be easily accessed. However, current US building codes prohibit installing a panel in a bathroom (or similar room), in closets intended for clothing, or where there is insufficient space for a worker to access it. Specific situations, such as an installation outdoors, in a hazardous environment, or in other out-of-the-ordinary locations may require specialized equipment and more stringent installation practices.

Large buildings or facilities with higher electric power demand may have multiple circuit breaker panels. In this case, the panels are often indicated by letters of the alphabet. One case is The Decon Gallery, a modern building in downtown Toronto, which has 11 breaker panels designated "A", "B", "C", "D", and so on. A backstage outlet is therefore labeled "C27". In many such buildings, each outlet is on its own circuit breaker, and the outlets are labelled in the above specified manner to facilitate easy location of which breaker to shut off for servicing, rewiring, or the like.

In even larger buildings, such as schools, hospitals and sports/entertainment venues it is not uncommon to have scores of panels, specially designated for each building depending on how the architects and electrical engineers subdivide the building. They are commonly designated as either three-phase or single-phase and normal power or emergency power. In these set-ups they may also be designated for their use, such as distribution panels for supplying other panels, lighting panels for lights, power panels for equipment and receptacles and special uses for whatever type of building they are used in. It is also not uncommon for these panels to be located throughout the building in electric closets serving a section of the building.

In a theatre a specialty panel called a dimmer rack is used to feed stage lighting instruments. A US style dimmer rack has a 208Y/120 volt 3 phase feed. Instead of just circuit breakers, the rack has a solid state electronic dimmer with its own circuit breaker for each stage circuit. This is known as a dimmer-per-circuit arrangement. The dimmers are equally divided across the three incoming phases. In a 96 dimmer rack, there are 32 dimmers on phase A, 32 dimmers on phase B, and 32 on phase C to spread out the lighting load as equally as possible. In addition to the power feed from the supply transformer in the building, a control cable from the lighting desk carries information to the dimmers in a control protocol such as DMX-512. The information includes commands on levels, fade times, and which dimmers come up and go out during the lighting changes of the show (light cues).

Distribution boards may be surface-mounted on a wall or may be sunk into the wall. The former arrangement allows for easier alteration or addition to wiring at a later date, but the latter arrangement may look neater, particularly in a residential situation. The other problem with recessing a distribution board into a wall is that if the wall is solid a lot of brick or block may need to be removed - for this reason recessed boards are generally only fitted on new-build projects when the required space can be built into the wall.

Mobile operation

Sometimes it is desired to have a portable breaker panel, for example, for special events. In this case, a breaker panel is mounted to a board, together with various sockets. These are common in the movie industry. The American one pictured at the right has a cord with an L21-30 plug to supply power. Power leaves the board through four three-phase circuits: three 15 ampere circuits; and one 20 A circuit. The 15 A circuits each go to a triplex-box. The 20 A circuit goes to an L21-20 receptacle, and one leg of it goes to a 20 A duplex receptacle shown at the upper left. The neon nightlights on the upper right triplex box are to show the phase presence.